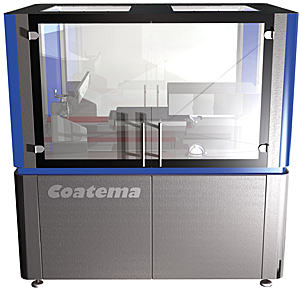

Easycoater

For Sheet-to-Sheet coating:

The Easycoater (third generation) is a discontinuous high-tech coating machine for Sheet-to-Sheet coating.

The Easycoater is designed to produce high quality products or samples in DIN A4 up DIN A0 quickly and reliably. A slot die, doctor blade, and flat screen-printing unit are available and many additional coating systems can be integrated.

The Easycoater is controlled by a Siemens S7 PLC processer and can create samples or small production quantities of products using various coating and printing methods. The plant is easy to use and offers an electrically heated dryer as standard and optional UV/infrared units. The Easycoater is fully encapsulated and is available in an EEx design. Source extraction is available in the coating area and a glove box configuration with an inert atmosphere is also possible.

Both the ultra-precise granite coating table in the vacuum table variant and the modular holder for the doctor blade and slot die can be motorized. The table movement under the coating system and then under the dryer can be defined in advance, enabling the drying cycle to be precisely regulated and repeated. If the motorized coating gap adjustment option is chosen, an adjustment in the 1µ range is possible. High precision, in every function, allows usage in technologies requiring top accuracy and consistence.