Basecoater and Basecoater 3G

Continuous large-scale coating:

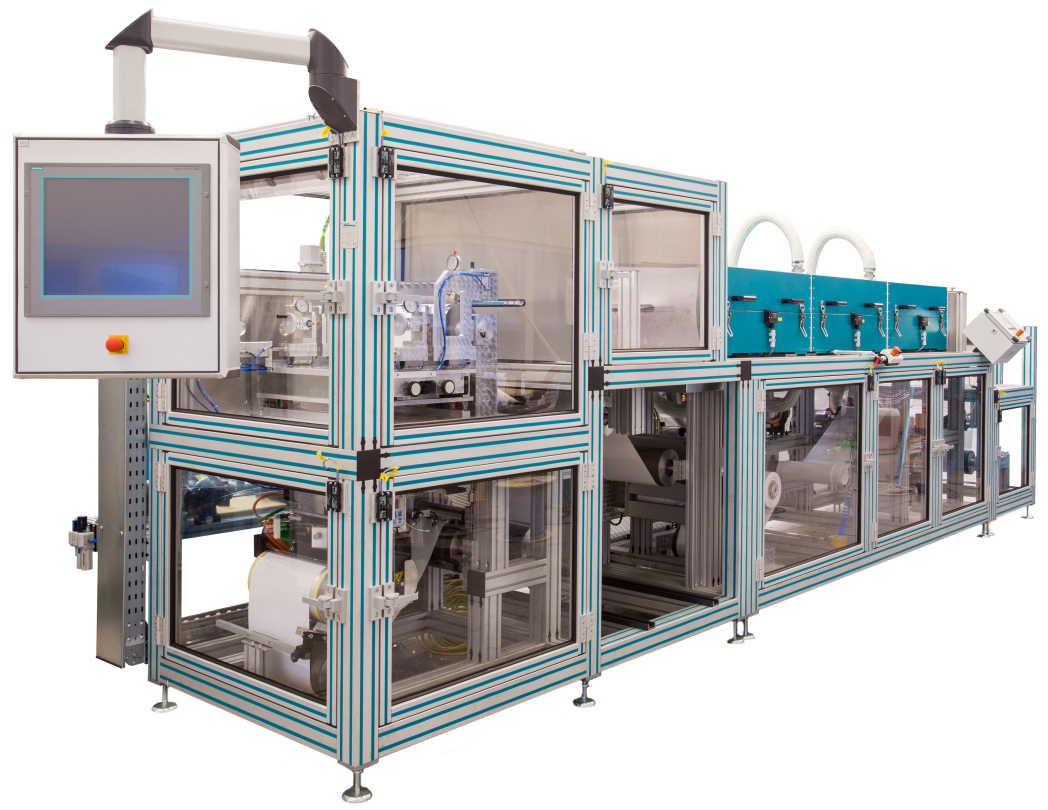

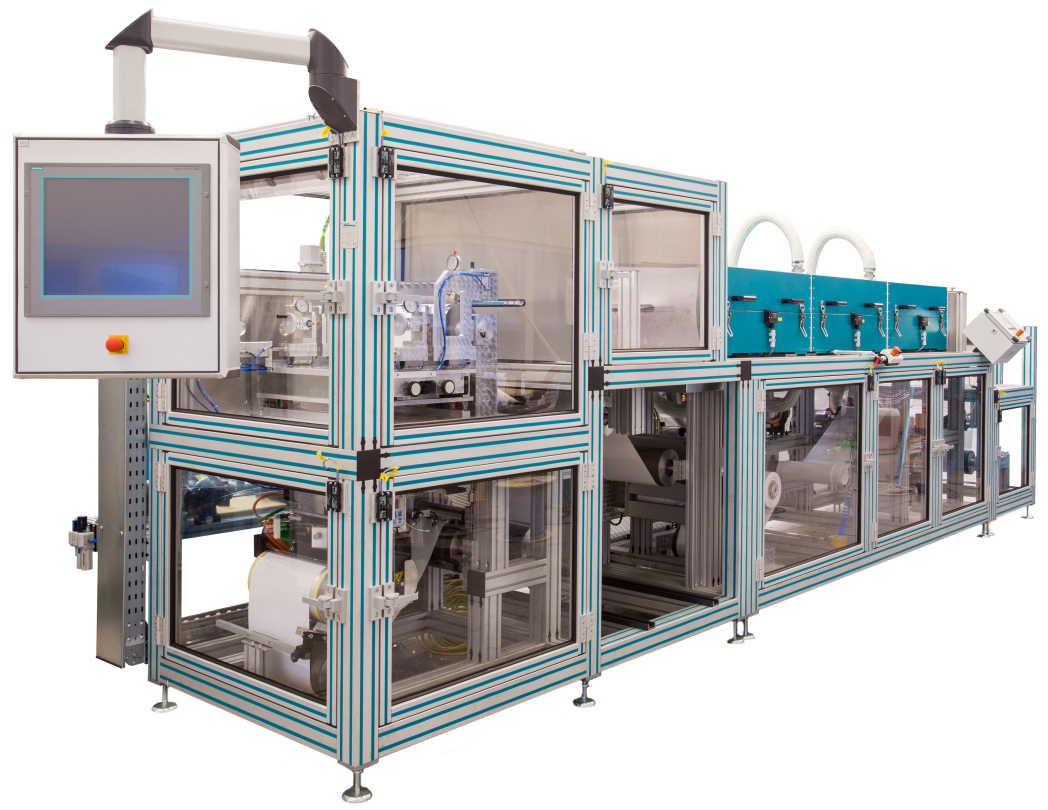

The Basecoater is a continuous Roll-to-Roll pilot/production coating plant.

The Basecoater was designed to deliver pilot and production quantities of coated and laminated products using the smallest possible quantities of substrates and chemicals. With a working width of between 200 mm and 1,000 mm, it can be used for textiles, films, paper and non-woven substrates. The plant was designed to offer maximum flexibility with reproducible parameters.

The Coatema Basecoater utilizes the modular Coatema system for quickly changing critical process components. This could include one or more coating systems or laminators, electrically heated dryers or an auxiliary PLC. It emulates the components of a large coating line with an attractive price-performance ratio.

For smaller working widths or quantities, the Basecoater is a better choice than jumping straight to using a large production plant.

Benefits

- Compact size/capabilities ratio

- Medium scale Roll-to-Roll

- More than 38 modular coating systems

- Wet and dry laminating systems

- Can be used for production

- Hotmelt systems can be used

- Low use of chemicals and substrates

- EEx layout available

- Many dryer variants

- Special machine construction solutions available

- GMP standard available

- Can be moved on rollers

- Economical weight/performance design

Possible equipment options

Coating systems

- Doctor blade

- Double side coating system

- Commabar

- Case doctor blade coating system

- Gravure printing roller

- 2-roller coating system

- 3-roller combi coating system

- Micro roller coating system

- 5-roller coating system

- Reverse roll coater

- Rotary screen printing

- Impregnation

- Slot die

- Curtain coating system

- Hotmelt slot die

- Powder scattering method

Dryers

- Electrical hot air dryer

- Flotation dryer

- IR dryer

- NIR dryer

- UV systems

- Inert systems possible

Additional options

- Hotmelt layout available, with many coating systems

- Calender up to 20t

- Cutting units for longitudinal and transverse profiles

- Special machine construction solutions

- GMP standard

- EEx layout possible

- Stamping unit

- Production layout for yarn coating

- Production layout for strip coating

Application areas

- Textiles

- Converting

- Batteries

- Fuel cells

- Printed electronics

- Solar cells

- Prepregs

Further info material