Coatema and SALD announce partnership on industrial Atomic Layer Deposition at CES 2022

7.1.2022 Dormagen / Eindhoven (ots)

Die Technologieschmiede SALD BV und der Maschinenbauer Coatema wollen die Technologie „Spatial Atomic Layer Deposition” (SALD) in die Massenproduktion bringen.

The tech-startup SALD BV and the mechanical and plant engineering company Coatema Coating Machinery GmbH announced a far-reaching development partnership at the CES 2022 innovation fair in Las Vegas last week. The common goal is to use the „Spatial Atomic Layer Deposition" (SALD) technology for industrial volume roll-to-roll production plants. In an R-2-R process („roll-to-roll”), a flexible base material is unrolled, a layer is coated or printed and the web is rolled up again, like the printing process of a newspaper.

Combined with the proprietary SALD technology, it is now possible to make nano-thin coatings with defined properties and functions in mass volume on the roll. Mass volume coating is essential for flexible electronic components, packaging films, and new solar and battery industry types.

In the first step, SALD BV and Coatema want to focus on battery technology, electrolysers and fuel cells. The new R2R process is particularly well suited for cost-effective mass production on a large scale.

Nano-coatings for mass production

SALD technology allows multiple atomic layers to be applied to each other, each as thin as a single atom. Nine layers on top of each other bring it to just one nanometer thick. Even such thin material coatings can trigger or prevent specific chemical processes, resulting in coatings with properties and functions that were previously considered unthinkable. The challenge is to transfer this technology from research labs into industrial mass production with flexible substrates such as plastic or thin metal foils. In this cooperation, SALD BV provides the nano-process technology for this purpose, and Coatema contributes the necessary R2R machinery.

„From Lab to Fab” (from the laboratory to the factory)

„For decades, manufacturing engineers have dreamed of using SALD in mass production. Now we are crossing this threshold and, together with Coatema, are bringing atomic layer coating technology from the laboratory to industry, i.e., from Lab to Fab,” explains Frank Verhage, CEO of SALD BV, proudly. Thomas Kolbusch, Director Sales, Marketing, Technology, VP of Coatema Coating Material, explains: „Coatema has been developing customer-specific machines and systems based on the latest technologies for over 40 years. Partnering with SALD BV brings us the expertise for Spatial Atomic Layer Deposition, one of the most promising basic nano technologies for general industrial use, which can significantly improve numerous products in various industries.” Erik Kremers, CTO of SALD BV, adds: „We are experiencing strong demand from industrial customers to bring SALD technology into mass production. We can satisfy this growing demand by cooperating with Coatema.”

An almost infinite range of functions

Numerous different materials such as metal oxides or nitrides can be applied to substrates by the Spatial ALD process. The SALD process makes an almost infinite range of material combinations (and thus functions) possible, depending on which materials are stacked on top of each other and the order in which they are used. As a result, complex compounds can be produced functionally on almost any surface.

This results in the vast industrial field of application of SALD technology, from chip production to battery cells, fuel cells, new flexible solar panels, to wafer-thin tear-resistant films for packaging in the food and consumer goods industry. This cooperation between Coatema and SALD extends to all areas of application in which the SALD roll-to-roll production process is used.

About Coatema Coating Machinery:

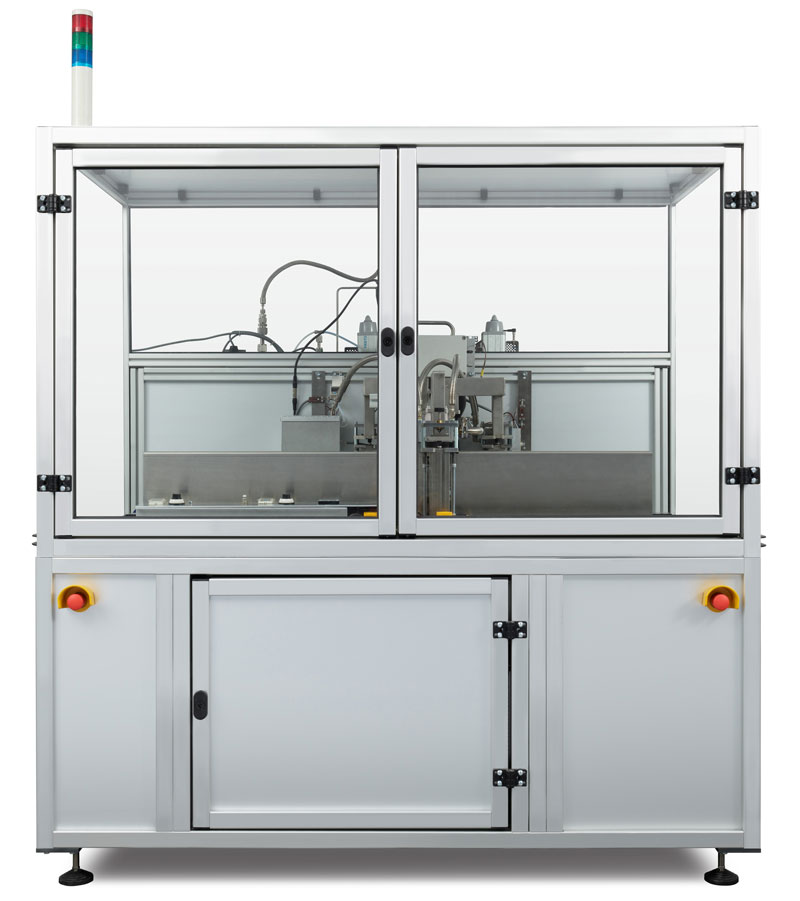

The innovative German machine builder Coatema Coating Machinery GmbH (www.coatema.de) has been offering flexible and efficient Lab2Fab solutions for coating, printing and lamination for more than 40 years. The business strategy and value proposition focus on innovation for growing markets with new demands on coating technologies such as printed electronics, sustainable packaging, membranes, renewable energy and medicine. The product portfolio covers the entire spectrum, from simple table-top solutions to fully comprehensive production lines. In the 1200 square meter research and development centre, customers can carry out basic research, process development and production of pilot and small production quantities on 13 different machine platforms with over 20 application systems.

About SALD BV:

With „Spatial Atomic Layer Deposition”, SALD (www.spatialald.com) has developed a globally unique, patented process for applying coatings as thin as a single atom on an industrial scale. These atomic coatings will revolutionize entire industries, including the production of battery cells for cars and smartphones, the textile industry, polymer electronics (organic computer chips), the solar energy industry and the packaging industry for consumer goods and convenience food. SALD uses a new logo.

See also press release from SALD BV

For more information on this press release please contact:

Marketing Manager Tanja Simone

Phone: +49 (0) 2133 / 97 84 - 121

E-Mail: This email address is being protected from spambots. You need JavaScript enabled to view it.